Using Sluices and Riffles for Efficient Recovery of Heavy Ores

Using Sluices and Riffles for Efficient Recovery of Heavy Ores

The mining industry has long utilized an array of methods for extracting valuable ore from the earth. Among these methods, sluices and riffles stand out as particularly effective tools in the recovery of heavy ores such as gold, tungsten, and heavy mineral sands. Their effectiveness is rooted in principles of fluid dynamics and sedimentology, which allow for the efficient separation of heavier materials from less dense ones. This article delves into the workings of sluices and riffles, their operational efficiencies, and their real-world applications in mineral extraction processes.

Fundamentals of Sluices and Riffles

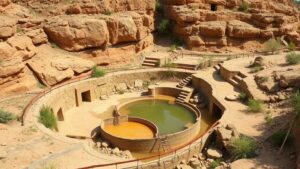

Sluices are essentially long, narrow troughs that guide water and materials down a gradient. Riffles are constructed within sluices, taking the form of barriers or obstructions that create turbulent flow. This turbulence is crucial, as it allows for the differential settling of materials based on density.

The primary mechanism at work in a sluice box is gravity. As water flows through the sluice, heavy materials settle behind the riffles, whereas lighter materials are washed further downstream. This process is aided by the shape and size of the riffles, which can be adjusted based on the particle size of the target ore.

Efficiency Metrics of Sluice and Riffle Systems

Efficiency in the context of sluices and riffles can be quantified through various metrics, notably recovery rates and the concentration ratio of heavy to light materials. Studies have shown that well-designed sluice systems can achieve recovery rates of up to 90% for heavy minerals under optimal conditions.

- Recovery Rate: The percentage of valuable material successfully extracted compared to the total material processed.

- Concentration Ratio: The ratio of recoverable heavy materials to lighter waste, indicative of system effectiveness.

To highlight the significance of these efficiencies, case studies of commercial operations reveal that mining operations can see significant increases in yield by optimizing sluice design and riffle placement. For example, a mine in Western Australia increased its gold recovery by 15% after retrofitting its sluice design.

Design Considerations for Sluices and Riffles

Proper design is critical for maximizing the effectiveness of sluices. Key considerations include:

- Riffle Height and Spacing: Riffles should be tailored to the size of the target ore. Taller riffles may capture larger particles, while closer spacing can enhance retention of finer materials.

- Water Flow Rate: The velocity of water can significantly influence recovery rates. Raised or lowered flow rates can ensure that heavy ores are not washed away prematurely.

- Slope of the Sluice: An ideal slope typically ranges between 2 to 5 degrees. A steeper angle may accelerate the water flow to a level that compromises recovery, while a flatter angle can reduce the velocity needed to disengage lighter material.

Real-World Applications in Heavy Ore Recovery

The practicality of sluices and riffles is evidenced by their widespread use in various mining sectors. For example, in artisanal gold mining, sluices are frequently deployed by individual miners to maximize recovery while minimizing ecological footprints. Notably, areas in South America have reported increased gold recovery rates by implementing correctly designed sluice systems instead of traditional panning methods.

In larger industrial settings, mining companies utilize sophisticated sluice systems equipped with automated water flow controls and variable riffle configurations. These advancements allow for real-time adjustments based on varying ore conditions, further increasing efficiency and recovery rates.

Addressing Common Concerns and Limitations

While sluice and riffle systems offer significant advantages, certain considerations must be taken into account. Common concerns include:

- Environmental Impact: The use of sluices involves water diversion and can disturb local ecosystems.

- Material Loss: Despite high recovery rates, some heavy ores may still be lost if not properly designed or monitored.

- Operational Cost: The initial investment in well-designed sluice systems can be substantial, which may deter smaller operators.

To mitigate these concerns, regulatory guidelines and best practices should be adhered to, ensuring that operations are sustainable and environmentally friendly.

Conclusion and Actionable Takeaways

The effective use of sluices and riffles represents a critical method in the recovery of heavy ores. By understanding the fundamental principles behind their operation, alongside optimizing their design, miners can significantly improve their recovery rates. As the mining industry continues to evolve, integrating modern technology with traditional techniques will be key to achieving sustainable mining practices that balance productivity with environmental stewardship.

In summary, to enhance ore recovery using sluices and riffles, consider the following actions:

- Assess the specific characteristics of the target ore to tailor the sluice design.

- Regularly monitor and adjust water flow rates to optimize recovery efficiency.

- Use a feedback system to continuously refine operation strategies based on real-time data.