Understanding Ventilation Requirements for Underground Mining Projects

Understanding Ventilation Requirements for Underground Mining Projects

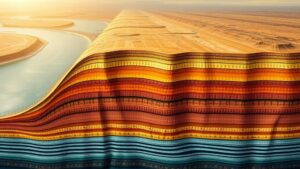

Ventilation is a critical component of underground mining projects, serving as a fundamental aspect of mine design and operations. Adequate ventilation systems are necessary to ensure the safety, efficiency, and health of workers in sometimes confined and hazardous environments. This article delves into the essential requirements for effective ventilation, the methodologies used, and the implications of inadequate ventilation in underground mines.

The Importance of Ventilation

The primary purpose of ventilation in underground mining is the control of air quality and temperature, as well as the removal of harmful gases, dust, and excessive heat. Key reasons for implementing effective ventilation systems include:

- Health and Safety: Ensuring the air is free from toxic gases such as carbon monoxide, methane, and radon is crucial for miner safety.

- Regulatory Compliance: Mining operations must meet local and international regulations that stipulate acceptable air quality and worker exposure limits.

- Operational Efficiency: Proper ventilation contributes to optimal working conditions, which can improve productivity and worker morale.

Ventilation Planning and Design

Effective ventilation planning and design are fundamental to the success of any underground mining project. The process involves several key considerations:

- Mine Layout: The design of the mine, including the arrangement of tunnels and shafts, directly impacts ventilation efficiency. For example, more complex layouts may require sophisticated ventilation systems.

- Airflow Requirements: Determining the required airflow rates is essential, which typically depends on the type of mining activities and the expected number of workers and machinery in the mine.

- Ventilation Control Methods: The use of fans, ductwork, and regulators can help direct and control airflow. Innovative solutions, like the use of jet fans or auxiliary fans, may enhance air movement in challenging areas.

Types of Ventilation Systems

There are two primary types of ventilation systems implemented in underground mining: general or main ventilation systems and local ventilation systems.

- Main Ventilation Systems: These systems are designed to circulate fresh air throughout the entire mine. They typically consist of primary fans and a network of ducts. A case in point is the use of large axial fans in deep mines, which can move significant volumes of air to maintain acceptable conditions across vast areas.

- Local Ventilation Systems: These are used in specific locations where equipment generates heat or pollutants, such as drill sites or ore passes. Examples include the use of localized exhaust fans that help to capture and remove contaminants away from workers.

Challenges to Effective Ventilation

Despite the importance of proper ventilation, several challenges can impede its effectiveness:

- Dynamic Conditions: The changing nature of mining activities and geological conditions can lead to fluctuating ventilation needs that require adaptive management strategies.

- Cost Implications: Useing and maintaining effective ventilation systems can represent a significant investment, particularly in deep or extensive mining projects.

- Monitoring and Compliance: Continuous monitoring of air quality is essential to comply with health regulations and manage risks. Technological advancements, such as sensors and automated systems, can aid in this effort but also require ongoing investment.

Case Study: The Role of Ventilation in a Successful Mining Operation

A prime example of effective ventilation management is the underground operations at the Cannington Silver Mine in Queensland, Australia. The mine employs a comprehensive ventilation system that utilizes both main and local ventilation approaches to manage air quality and temperature effectively. By continuously monitoring air quality parameters, the mine has maintained compliance with safety regulations while enhancing worker productivity.

Future Trends in Mine Ventilation

The future of ventilation in underground mining is poised for innovation as new technologies emerge. Trends include:

- Automation: Automated ventilation systems capable of adjusting airflows in real time based on mining activities or mine conditions can optimize resource use and enhance safety.

- Energy Efficiency: Improved fan designs and alternative energy sources, such as renewable energy, may reduce energy consumption associated with ventilation.

Conclusion and Actionable Takeaways

Understanding the ventilation requirements of underground mining projects is essential to ensuring safety, health, and operational efficiency. By investing in robust ventilation planning, adopting innovative technologies, and adhering to regulatory standards, mining operators can mitigate risks and enhance the working environment for miners. As the industry evolves, staying informed about best practices and developments in ventilation technology will be vital for long-term success in underground mining operations.