The Role of Sluices and Launders in Agricola’s Ore Recovery Processes

The Role of Sluices and Launders in Agricola’s Ore Recovery Processes

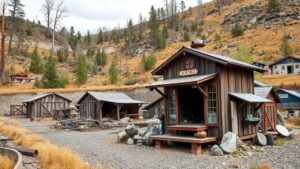

In the field of early modern mining, the utilization of sluices and launders played a crucial role for metallurgists, particularly noted in the works of Georgius Agricola. His seminal text, De Re Metallica, published in 1556, meticulously details the processes involved in the extraction and processing of minerals. This article delves into the functionality, importance, and advancements of sluices and launders in ore recovery as documented by Agricola.

The Functionality of Sluices

Sluices are engineering marvels designed to direct and control the flow of water, thereby separating valuable ores from waste materials. In ore processing, sluices function by harnessing the hydraulic power of flowing water. The principle of gravity assists in the separation of denser materials, such as gold and silver, from lighter debris.

- Water flows over the sluice, carrying both light and heavy materials.

- As the water slows upon entering the sluice, heavier particles settle to the bottom while lighter particles are carried away.

In Agricola’s era, sluices were often constructed from wood and lined with various materials, including cloth and moss, to enhance particle capture. A notable case is the use of finely woven burlap in sluices, which improved retention and facilitated the recovery of fine gold particles, which were notoriously challenging to capture.

Advantages of Launders

Launders are crucial components in the transportation of slurry–essentially a mixture of crushed ore and water–through the mining process. are typically channels or tubes designed to carry the material from one processing station to another, often leading to the sluicing system. The following are the primary advantages of launders:

- Minimize spillage and loss of valuable materials during transport.

- Help efficient routing of water and slurry to optimize recovery rates.

Agricola emphasized the importance of well-constructed launders, noting that a loss in slurry could significantly decrease overall yield. Utilization of launders also reduced the overall labor needed, as miners could set up a more continuous processing line. In some cases, launders were even elevated to harness gravitational flow, thereby optimizing energy use.

Over time, significant advancements in sluice and launder technology were observed. Agricola documented the eventual transition from simple wooden structures to more complex designs that incorporated metal fittings, improving durability and efficiency. A specific example can be noted in the introduction of adjustable gates in sluices, which allowed operators to better control water flow and improve the separation process. This level of automation is an early precursor to modern hydraulic engineering techniques.

Case Studies: The Efficiency of Sluices and Launders

Historically, the introduction of sluices and launders resulted in dramatic improvements in ore recovery efficiency. For example, miners working in the alluvial goldfields reported that they could recover up to 90% of gold deposits, a marked enhancement over previous methods involving manual panning and sieving. This increase in efficiency not only made mining operations more profitable but also contributed to the broader economic development of mining regions.

Another example can be drawn from the operation of the early lead-mining districts, where sluices and launders were vital in handling the large quantities of water generated in deep mines. Agricola documented cases where the combination of these systems allowed for effective management of mine drainage, enabling longer and deeper mining operations.

Conclusion and Actionable Insights

The contributions of sluices and launders to ore recovery processes, as articulated by Georgius Agricola, laid the groundwork for modern mining techniques. Understanding their functionalities and advantages can offer valuable insights into the efficiency of contemporary mining operations. Key takeaways include:

- Integrate sluice designs that enhance particle capture and recovery rates.

- Ensure launder systems are optimized for minimal material loss and effective transport.

- Invest in continuous improvements in materials and structural integrity for sustainable mining practices.

As the mining industry continues to evolve, examining historical practices such as those described by Agricola offers a vital lens through which to innovate and refine modern ore recovery techniques.