The Role of Ore Storage Bays in Agricola’s Mining Systems

The Role of Ore Storage Bays in Agricola’s Mining Systems

Agricola’s mining systems, including ore storage bays, are crucial to ensure the efficient extraction and management of minerals. As mining operations become more complex, understanding the functionality and importance of these storage facilities is essential for optimizing resource use and minimizing operational costs.

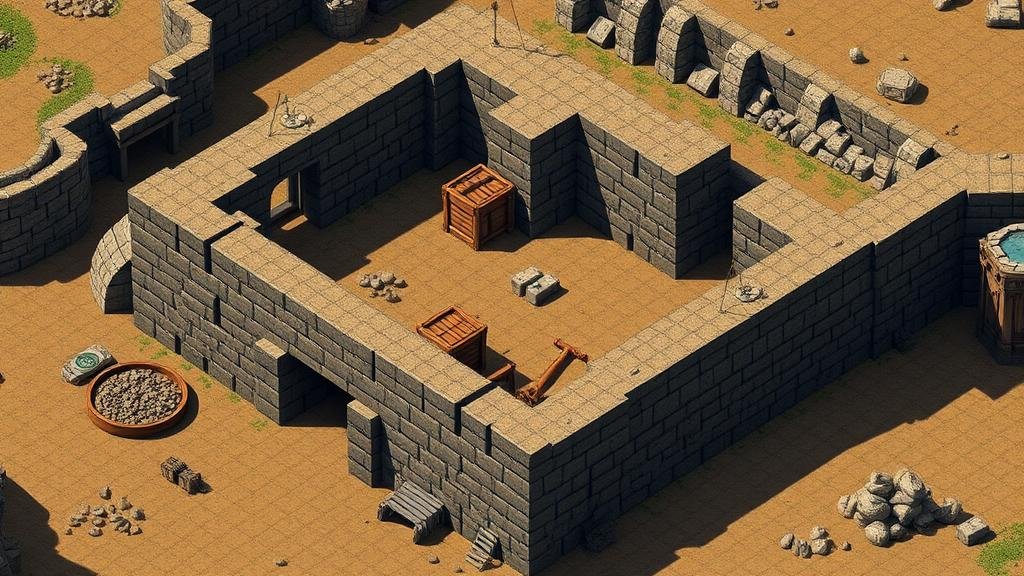

Understanding Ore Storage Bays

Ore storage bays, often viewed as ancillary components in mining operations, serve critical purposes in the logistics of mineral management. These bays are designed to temporarily hold ore extracted from mines before processing or transportation. r design and location can significantly affect the speed and efficiency of mining operations.

The Importance of Location and Design

The positioning of ore storage bays plays a vital role in reducing transportation costs and time. Optimal locations should be as close to the point of extraction as possible to decrease handling costs. For example, a study conducted in Australian iron ore mines demonstrated that strategically placing storage bays within a 500-meter radius of the extraction site can reduce transportation costs by approximately 15%.

Also, the design of these bays impacts the operational efficiency. For example:

- Base surface material must be durable to withstand heavy loads and seasonal weather changes.

- Ample space must be allocated to prevent congestion, allowing for seamless loading and unloading operations.

Environmental Considerations

In modern mining practices, environmental sustainability is of utmost importance. Ore storage bays can pose risks such as contamination of local water sources if not properly managed. To mitigate these concerns, mining companies are implementing stricter environmental controls. For example, using impermeable liners in storage bays can prevent leachate from escaping and contaminating the surrounding ecosystem. In regions like South Africa, companies that adopted these practices reported a 40% decrease in environmental compliance issues.

Real-World Applications

In practical terms, several mining companies have successfully integrated innovative storage solutions in their operations. One notable instance is the implementation of automated ore handling systems in mines like those in the Canadian nickel sector. e systems enhance real-time monitoring of ore levels within storage bays, ensuring that logistics and supply chain operations remain sync with production rates.

- Examples include the use of sensors to manage inventory levels, allowing for on-demand processing and reducing buffer stock requirements.

- Automation technology can also minimize human error and improve overall safety by limiting personnel around potentially hazardous areas.

Future Trends in Ore Storage Bays

Looking ahead, advances in technology are expected to revolutionize the functionality of ore storage bays. The integration of artificial intelligence (AI) and the Internet of Things (IoT) will pave the way for smarter management systems.

- Predictive analytics can forecast ore demand based on historical data, allowing for more effective storage management.

- Remote monitoring systems can be implemented to oversee conditions within storage bays continuously, enhancing safety and efficiency.

Conclusion

To wrap up, ore storage bays are not merely incidental aspects of mining operations; they are integral to the efficiency, safety, and environmental management of mining systems. By optimizing their location, design, and management practices, companies can enhance productivity and sustainability. As technology evolves, the role of these storage facilities will likely expand, presenting new opportunities for mining operations to operate more effectively in a competitive landscape.