The Basics of Aligning Drifts and Shafts for Ore Body Access

The Basics of Aligning Drifts and Shafts for Ore Body Access

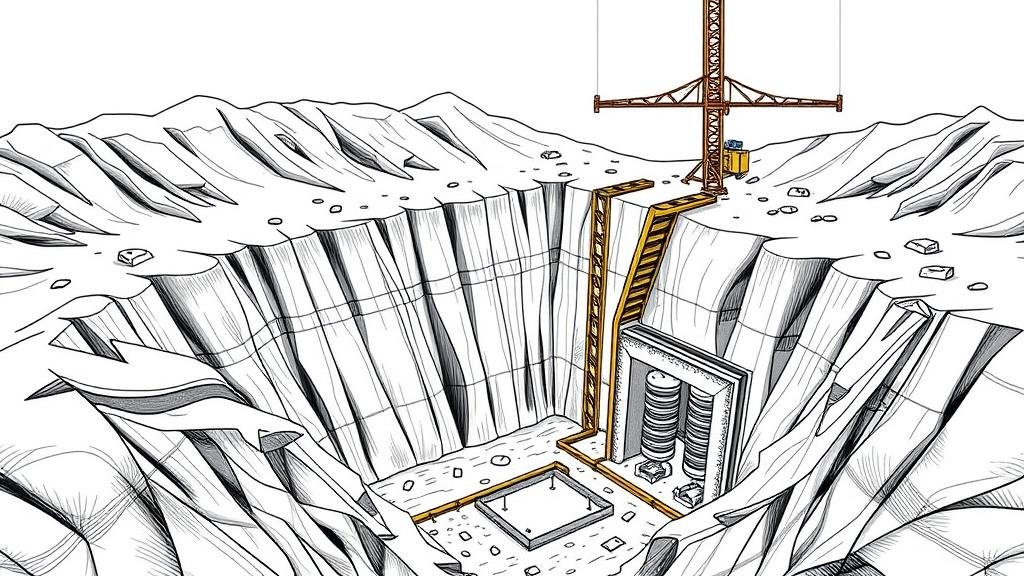

Aligning drifts and shafts is a critical process in underground mining that ensures efficient access to ore bodies. The alignment affects not only the safety and efficiency of the extraction process but also the long-term sustainability of the mining operation. Understanding the basics of this process is essential for mining engineers and professionals in the sector.

Understanding Drifts and Shafts

Drifts are horizontal passages that facilitate access to ore bodies, while shafts are vertical or steeply inclined passages that connect the surface to underground operations. Proper alignment of these passages is vital for several reasons:

- Efficient material handling

- Accessibility for machinery and personnel

- Minimization of rock movement and deformation

The Importance of Alignment

The alignment of drifts and shafts can significantly impact various aspects of mining operations, including:

- Safety: Poor alignment can lead to dangerous conditions, including rockfalls and reduced access for emergency evacuation.

- Efficiency: Well-aligned passages reduce the need for additional transport equipment and optimize ore extraction rates.

- Cost-effectiveness: Achieving the correct alignment can minimize unnecessary excavation, thus reducing operational costs.

Methods of Alignment

There are several methods employed in aligning drifts and shafts, each with its own advantages and applications:

- Geodetic Methods: Utilizing precise surveying techniques to establish horizontal and vertical references. For example, using total stations to measure angles and distances helps in creating a detailed layout of the underground passages.

- Laser Scanning: Laser technology can be employed to scan the alignment of drifts and shafts in real-time. This method enhances accuracy and efficiency, providing immediate feedback regarding the alignment.

- GPS Technology: Global Positioning Systems can be adapted for underground use to provide accurate location data, ensuring that drifts and shafts are aligned as designed.

Real-World Applications

To illustrate the importance of alignment, consider the case study of the Oyu Tolgoi mine in Mongolia. mine employs advanced geodetic methods to maintain shaft alignment during the construction phase. Misalignment could lead to significant delays and financial losses due to the complex underground geology of the region.

Similarly, in the Sudbury Basin of Canada, the use of laser scanning has enhanced the alignment process, allowing mining companies to adapt quickly to unexpected geological conditions. This proactive approach minimizes inefficiencies and potential hazards.

Challenges in Alignment

While aligning drifts and shafts is essential, several challenges can complicate the process:

- Geological Variability: Changes in rock type can cause shifts in alignment due to varying deformation characteristics.

- Water Ingress: Water can erode drift alignments, making regular monitoring essential.

- Technological Limitations: In remote locations, access to advanced surveying technologies can be limited.

Actionable Takeaways

To ensure successful alignment of drifts and shafts for ore body access, mining professionals should:

- Invest in modern surveying and alignment technologies.

- Regularly monitor passages for any signs of misalignment or deformation.

- Conduct training sessions to keep personnel updated on best practices in alignment methods.

By focusing on proper alignment of drifts and shafts, mining operations can enhance safety, efficiency, and profitability in the extraction of ore resources.