Techniques for Reinforcing Tunnel Junctions Using Agricola’s Guidelines

Techniques for Reinforcing Tunnel Junctions Using Agricola’s Guidelines

Reinforcing tunnel junctions is a critical aspect of mining engineering and construction, particularly in enhancing stability and safety in underground operations. Agricolas guidelines offer foundational principles that can be adapted to modern techniques, ensuring durability and resilience during the excavation process. This article explores various reinforcement methods, systematic applications, and their implications for tunnel integrity.

Understanding Tunnel Junctions

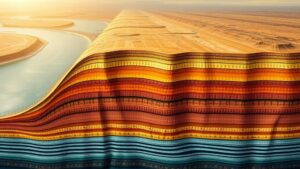

Tunnel junctions are intersections where two or more tunnels converging create points of potential structural weakness. An effective reinforcement strategy is essential to manage soil and rock pressures, which can vary significantly due to geological conditions. Farmers of yore innovated (as highlighted by Agricola) through trial and error, and modern engineers build on these foundational lessons.

Key Reinforcement Techniques

A comprehensive approach to reinforcing tunnel junctions can be segmented into the following techniques:

- Rock Bolt Installation: This technique involves inserting steel bolts into rock masses to stabilize the surrounding soil. According to the Colorado School of Mines, effective rock bolting can increase the load-bearing capacity of tunnel walls substantially.

- Steel Mesh and Shotcrete: The application of a steel mesh reinforced with shotcrete provides an immediate structural support layer that enhances the integrity of tunnel junctions quickly. A case study from the London Crossrail project demonstrated shotcretes effectiveness in high-stress environments.

- Grouting: Injection of cementitious or chemical grouts into surrounding rock can fill voids and enhance bond strength. Studies illustrate that grouting can improve stability by up to 25% in compromised ground conditions, effectively stabilizing junctions.

- Steel Arches: This method employs pre-fabricated steel arches to maintain the shape of a tunnel while redistributing loads away from junction points. The New Austrian Tunneling Method (NATM) utilizes this technique for its adaptability in varying geological conditions.

Applications in Real-World Scenarios

Real-world applications of these techniques underline their effectiveness. For example, the reinforcement strategies employed in the Gotthard Base Tunnel in Switzerland combined rock bolts, shotcrete, and steel arches, allowing the tunnel to maintain its integrity under extreme geological stress.

Another pertinent example is the use of grouting in the Channel Tunnel, where it played a vital role in sealing water ingress issues, consequently stabilizing junction intersections. The successful application of these methodologies reflects Agricolas emphasis on empirical observation leading to effective engineering solutions.

Challenges and Considerations

While each reinforcement technique presents its advantages, engineers must also consider potential challenges:

- Geological Variability: As soil and rock conditions can differ dramatically within short distances, a thorough geological survey is critical.

- Creep and Settlement Risks: Prolonged loading may lead to creep, requiring ongoing monitoring and adaptive strategies.

- Cost Implications: Useation of reinforced solutions can be costly, necessitating a careful analysis of long-term benefits against immediate investments.

Conclusion and Actionable Takeaways

Incorporating Agricola’s guidelines provides a valuable framework for understanding and implementing tunnel junction reinforcement techniques today. It is essential to analyze geological conditions, maintain meticulous documentation of reinforcement strategies, and adapt methods based on ongoing assessments.

In light of these considerations, it is recommended that:

- Conduct comprehensive geological studies prior to tunnel junction reinforcement.

- Engage in continuous monitoring after reinforcement implementation to ensure structural integrity.

- Invest in training and development for engineers on the latest reinforcement techniques and technologies.

By combining historical insights with modern scientific advancements, mining engineers can enhance the reliability and safety of tunnel junctions, ensuring successful underground operations.