Techniques for Managing Spoil Removal in Confined Mining Spaces

Techniques for Managing Spoil Removal in Confined Mining Spaces

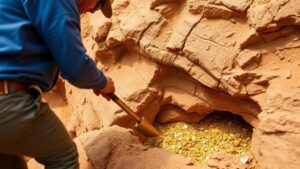

Mining operations in confined spaces present unique challenges, primarily related to spoil removal. In these environments, the effective management of spoil is essential for ensuring safety, productivity, and the economic viability of mining activities. This article outlines various techniques for managing spoil removal in confined spaces, supporting each method with real-world applications and case studies.

Understanding Spoil and Its Implications

Spoil refers to the waste material that is produced during mining operations. This includes soil, rock, and other material that must be excavated to access the desired mineral. In confined mining spaces, spoil removal is complicated by limited access, safety concerns, and potential impacts on surrounding environments.

1. Optimization of Spoil Removal Processes

One fundamental technique for managing spoil removal is optimizing the processes involved. This includes the utilization of advanced technologies and methodologies to streamline operations.

- Automated Systems: The implementation of automated hauling systems can significantly reduce the labor required for spoil removal. For example, the use of automated trucks in the underground mining industry has been shown to improve efficiency while minimizing human risk.

- Predictive Analytics: By employing predictive analytics based on historical data, mining operations can better forecast spoil generation and plan for removal accordingly. This was effectively demonstrated in a case study at the Grasberg Mine in Indonesia, where data-driven strategies enhanced logistical operations.

2. Tailored Spoil Management Plans

Every mining project is unique, necessitating tailored spoil management plans. A thorough assessment of the mining environment, geology, and operational constraints should inform these strategies.

- Environmental Considerations: Incorporating environmental stewardship into spoil management can mitigate the negative effects of spoil. The implementation of effective drainage systems in the De Beers’ Venetia Mine in South Africa is a prime example, where spoil is managed to prevent environmental degradation.

- Adaptive Techniques: Flexibility in spoil management strategies allows for adaptation to changing conditions within the mine. Case studies from the Cannington Mine in Australia highlight the importance of modifying removal processes in response to geological variances.

3. Enhanced Transportation Systems

Transportation systems play a crucial role in the effective removal of spoil. Employing specialized vehicles and track systems can enhance the efficiency of spoil transport within confined mining environments.

- Conveyor Systems: The installation of conveyor belts can facilitate continuous spoil removal, reducing bottlenecks at transfer points. use of conveyor belts at the Mponeng Mine exemplifies how this system can improve spoil handling efficiency.

- Mobile Haulage Equipment: Utilizing mobile haulage equipment, such as scoops and shuttle cars, can provide flexibility in operations. The success of this approach has been evidenced at the LaRonde Mine in Canada, where mobile equipment is paired with strict logistical planning to optimize operations.

4. Safety Protocols in Spoil Management

Prioritizing safety during spoil removal is vital, especially in confined spaces. Useing robust safety protocols is essential to protect workers while maintaining productivity.

- Training and Certification: Continuous training ensures that workers are equipped to manage spoil safely. Mining companies, such as Rio Tinto, have invested heavily in training programs that focus on safe spoil handling and emergency response.

- Monitoring Systems: Deploying real-time monitoring systems can help manage risks associated with spoil removal. The use of drones for site assessments at the Donkin Mine in Canada has demonstrated how technology can be leveraged to enhance safety protocols.

5. Innovations in Spoil Treatment

Innovative techniques in spoil treatment can also contribute to effective spoil management. These alternatives can minimize environmental impacts while maximizing resource recovery.

- Recycling and Reuse: Advanced technologies have facilitated the recycling of mining spoil for construction purposes. The Mount Isa Mines in Australia effectively recycle spoil, showcasing a sustainable approach that benefits both the industry and the environment.

- Soil Stabilization Techniques: Soil stabilization advancements allow for the safe reintegration of mined soil back into the environment. Techniques such as the use of geopolymers have been applied effectively in various projects to enhance soil characteristics.

Conclusion and Actionable Takeaways

Effectively managing spoil removal in confined mining spaces requires the integration of optimized processes, tailored management plans, enhanced transportation systems, stringent safety protocols, and innovative treatment methods. By employing these techniques, mining operations can not only improve efficiency and safety but also contribute positively to environmental conservation. The lessons gleaned from leading mining operations worldwide can provide a foundational framework for future advancements in the field of spoil management.

Actionable takeaways include:

- Conduct thorough assessments of mining operations to tailor spoil management plans effectively.

- Invest in automation and transportation innovations to optimize spoil removal processes.

- Use comprehensive safety training and monitoring to protect workers.

- Explore recycling and innovative treatment methods for sustainable spoil management.