How to Process Carbonaceous Ore Without Specialized Equipment

How to Process Carbonaceous Ore Without Specialized Equipment

Carbonaceous ores, which contain organic materials like carbon, present unique challenges for extraction and processing. Conventional mining and processing techniques often require specialized equipment that may not be readily available to small-scale miners or hobbyists. But, there are several methods to process carbonaceous ore effectively using simple tools and techniques.

Understanding Carbonaceous Ore

Carbonaceous ores are primarily characterized by their high carbon content, often derived from plant material, which can complicate traditional extraction methods. Examples include coal, certain types of petroleum, and organic-rich shales. Understanding the nature of these ores is crucial for developing effective processing techniques.

Initial Assessment and Preparation

Before beginning the processing of carbonaceous ore, a thorough assessment of the ore is vital. This involves examining the mineral composition, identifying the carbon content, and determining the overall quality. Once assessed, the ore should be crushed to increase surface area and enhance the efficiency of subsequent processing steps.

- Use a hand-operated mortar and pestle or a simple rock crusher to break down larger pieces of ore.

- Fine grinding increases the leaching effectiveness and allows for better separation of valuable minerals.

Separation Techniques

With finely crushed ore, the next step involves separation of the carbonaceous material from non-carbonaceous constituents. Several straightforward techniques can be employed:

- Water Separation: Utilizing water, one can create a slurry where lighter carbon constituents float, allowing for easier collection. This is particularly effective for certain forms of coal.

- Gravity Separation: By using simple devices like a sluice box, one can separate heavier minerals from lighter organic material based on density differences. This method is widely used in gold recovery but can be adapted for carbonaceous ores.

Enhancing Recovery with Pyrolysis

To further extract valuable materials from carbonaceous ores, one can use a method known as pyrolysis, which involves heating the ore in the absence of oxygen. This process converts organic components into gas, oil, and char. Here’s how to set up a basic pyrolysis system:

- Materials Needed: A metal drum, solid fuel (like wood or charcoal), and a collection container for gases.

- Process: Load the crushed ore into the drum and seal it tightly. Set the drum over a fire made from the solid fuel. As the temperature rises, organic materials will break down, releasing gases while leaving behind carbon in the form of char.

This process can be managed without sophisticated equipment and can yield useful outputs, such as biochar, which improves soil health and can be used as a fuel source.

Environmental and Safety Considerations

While processing carbonaceous ore using low-tech methods can be advantageous, it is essential to consider environmental and safety issues. Pyrolysis can release volatile organic compounds (VOCs) if not managed correctly. efore, care must be taken to vent gases safely. Also, working with hazardous materials may require protective equipment to ensure safety.

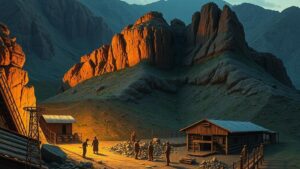

Case Studies and Real-World Applications

There are various small-scale operations around the world successfully utilizing these methods. For example, artisanal miners in certain regions of Africa implement gravity separation techniques without heavy machinery, achieving efficient mineral recovery while maintaining local traditions. e practices not only showcase the viability of low-tech processing but also provide economic opportunities in remote areas.

Conclusion and Actionable Takeaways

Processing carbonaceous ore without specialized equipment is feasible with careful planning and the implementation of simple techniques. Techniques like grinding, water separation, and pyrolysis can yield valuable products while promoting sustainable practices.

- Conduct thorough ore assessments before processing.

- Use simple grinding and separation technologies to maximize recovery.

- Consider pyrolysis for further extraction and value addition.

- Prioritize environmental safety during all processing stages.

By applying these methods, individuals and small operations can successfully process carbonaceous ores while minimizing reliance on expensive, specialized equipment.