How to Build Water-Driven Ore Lifts Using Agricola’s Designs

How to Build Water-Driven Ore Lifts Using Agricola’s Designs

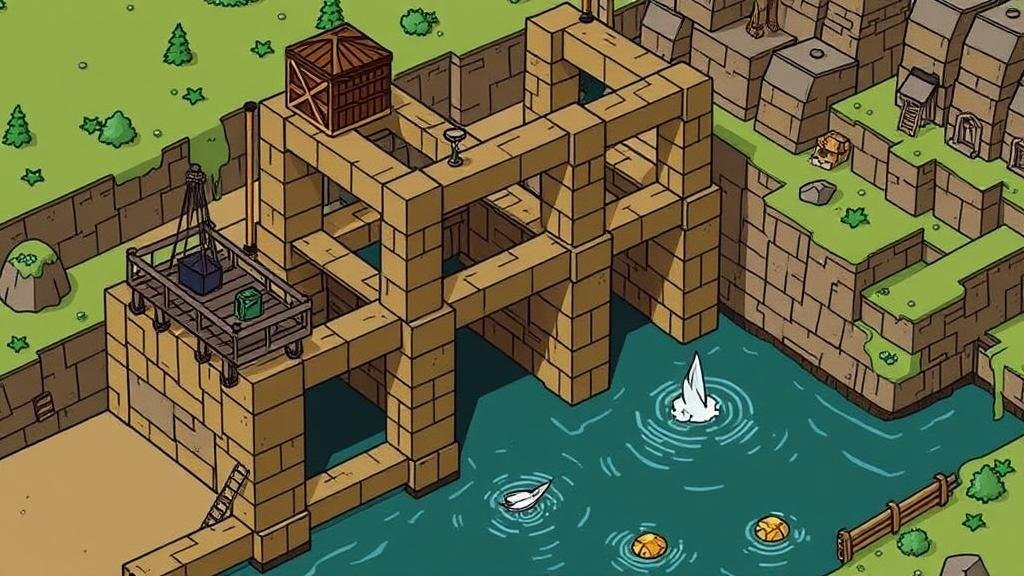

Water-driven ore lifts, also known as water wheels or water-powered hoists, represent a fascinating intersection of ancient engineering and contemporary mining practices. The designs proposed by Agricola in his seminal work, De re metallica, laid the groundwork for understanding how to effectively harness water power for the transportation of ores. This article will cover the fundamental aspects of building these ore lifts using Agricola’s principles.

The Principle of Water-Driven Ore Lifts

Water-driven ore lifts operate on the principle of converting the kinetic energy of flowing water into mechanical energy. This mechanical energy is used to lift ore from mines to the surface for processing. Agricola’s designs emphasized both efficiency and sustainability, demonstrating how natural resources can be utilized responsibly.

Key Components of Water-Driven Ore Lifts

Building a water-driven ore lift requires a thorough understanding of its key components:

- Water Source: A reliable and consistent water supply is crucial. Rivers or streams with suitable flow rates are ideal.

- Water Wheel: The wheel is the heart of the operation. It is typically constructed from wood and must be designed to maximize rotation from the waters force.

- Axle and Gear System: The axle connects the water wheel to the lifting mechanism. Gears may be included to enhance lifting efficiency.

- Lifting Mechanism: Commonly a bucket system or an endless chain, which transports the ore to the surface.

Construction Process

Follow these general steps to construct an effective water-driven ore lift:

Step 1: Selecting the Site

Choose a location with ample water flow and suitable terrain for supporting the structure. Elevation is also important; a steep incline allows for better flow and power generation.

Step 2: Building the Water Wheel

Construct the water wheel from durable wood, ensuring it is large enough to catch the water’s flow effectively. wheel should be mounted on a sturdy axle, allowing for smooth rotation.

Step 3: Installing the Gear System

Integrate a gear system to amplify the rotational force. Depending on the design, these may be simple bevel gears or more complex arrangements that provide greater lifting capacity.

Step 4: Setting Up the Lifting Mechanism

Attach the lifting mechanism to the axle. Options include a system of buckets or a chain with scoops, designed to securely transport ore from the mine to the surface.

Examples and Historical Context

Agricola’s principles can be observed in various historical mining sites. For example, the Roman mining operations in Spain effectively utilized similar water-driven hoists to extract valuable minerals. In modern times, remnants of these systems are found in mining museums, demonstrating their long-lasting significance.

Potential Benefits and Challenges

Utilizing water-driven ore lifts provides numerous benefits, including:

- Sustainability: Renewable energy source reduces reliance on fossil fuels.

- Cost-Effectiveness: Low operational costs, once built, as water flow is typically free.

But, challenges include:

- Maintenance: Regular upkeep is needed to combat water damage and wear and tear.

- Site Dependability: Variability in water supply can affect operations.

Conclusion

Building water-driven ore lifts following Agricola’s designs not only provides a glimpse into ancient engineering techniques but also highlights the potential for renewable energy in mining operations today. By understanding the principles and components involved, miners can harness the power of water for efficient ore extraction.

For practical implementation, interested parties should conduct a site assessment and engage skilled artisans for construction to ensure safety and efficiency. Also, modern technologies such as sensors and automation could enhance the performance of these historic designs, bridging the gap between ancient wisdom and modern innovation.