Exploring Historical Lime Kiln Sites for Forgotten Manufacturing Tools

Exploring Historical Lime Kiln Sites for Forgotten Manufacturing Tools

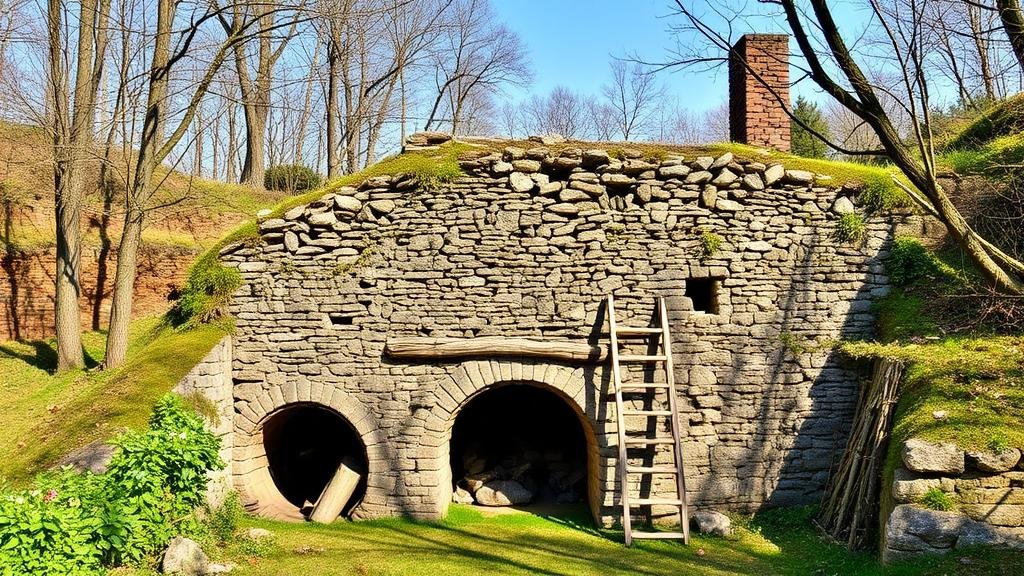

The study of historical lime kiln sites presents an intriguing opportunity to uncover forgotten manufacturing tools and techniques integral to the industrial and pre-industrial landscapes. This research article delves into the historical significance of lime kilns, their geographical distribution, and the tools associated with their operation and production. Insights will be drawn from various case studies showcasing the archaeological importance of lime kilns across North America and Europe.

The Historical Significance of Lime Kilns

Lime kilns have played a crucial role in various industries since Roman times, primarily in the production of quicklime (calcium oxide) from limestone. This produced material was essential for agricultural practices, construction, and various chemical processes. The significance of lime kilns is further highlighted by the fact that lime production has been traced back over 2,000 years, with various regional techniques developing over time.

For example, the lime kiln in the town of Catoosa, Oklahoma, built in 1914, was pivotal in supplying lime for local agricultural purposes. Similarly, the Ashburnham lime kiln in Massachusetts, dating back to the mid-19th century, provided lime for construction projects that shaped the regions infrastructure. Such kilns have become cultural and historical landmarks, providing clues to the technological advancements of their time.

Geographical Distribution and Archaeological Evidence

The geographical distribution of lime kilns can be broadly categorized into two major regions: North America and Europe. In North America, particularly in the regions of the Midwest and Northeast, lime kilns were essential in supporting the booming agricultural industries and developing urban centers.

In Europe, countries such as England, Ireland, and Germany showcase a rich heritage of lime kiln structures, with some operational sites dating back to the early 19th century. Archaeological evidence in these regions typically includes remnants of the kilns themselves–constructed from stone or brick–and associated tools, such as tongs, shovels, and various measuring devices.

- North American Sites: Catoosa, Oklahoma; Ashburnham, Massachusetts.

- European Sites: The Peak District in England; the limestone mining region of Bavaria, Germany.

The Tools of Lime Production

The tools utilized in lime production were often simple yet effective, reflecting the practical needs of the time. Key manufacturing tools included:

- Lime Burners: Equipment used to achieve the necessary temperatures for calcination.

- Slaking Vats: Containers for mixing quicklime with water to produce hydrated lime.

- Measuring Tools: Scales and other instruments for precise ingredient assessments.

For example, the presence of lime burners not only indicates the technological prowess of the period but also provides insights into local materials and labor practices. The slaking vats made from wood or stone illustrate the adaptation of available resources to meet production needs.

Case Studies of Archaeological Findings

Several case studies highlight the importance of investigating historical lime kilns as archaeological sites. A notable case is the lime kiln site at Kilmartin Glen in Scotland, where excavations have revealed various tools used in lime production that date back to the 3rd century AD. Researchers found evidence of both domestic and commercial lime production, shedding light on societal needs at the time.

In America, the analysis of the Ashburnham kiln revealed various late-19th-century tools that align with local construction practices of the time. Artifacts including stone hammers, measuring boards, and remnants of the kiln structure indicate a thriving industry tied to the local economy.

Challenges and Future Directions

Despite their historical significance, many lime kiln sites face challenges, including urban development, neglect, and environmental factors. Preservation efforts must be prioritized to safeguard these archaeological sites and the cultural heritage they represent.

Future research can benefit from interdisciplinary approaches, combining archaeology with historical analysis and environmental science to create comprehensive studies of lime kilns and their contexts. Contemporary methodologies, such as remote sensing and 3D modeling, should also be employed to enhance documentation and facilitate educational outreach.

Actionable Takeaways

Exploring historical lime kiln sites can yield invaluable insights into past manufacturing practices and tools. Stakeholders in heritage conservation, local governments, and educational institutions should consider the following actionable steps:

- Conduct regular surveys of lime kiln sites to document physical conditions and artifacts.

- Engage local communities in heritage preservation activities, fostering a sense of ownership and responsibility.

- Integrate findings into educational programs focused on industrial history and archaeology.

By taking these steps, we can ensure the continued exploration and preservation of lime kiln sites as crucial components of our historical manufacturing narrative.