Building Inclined Planes for Efficient Ore Hauling in Underground Mines

Building Inclined Planes for Efficient Ore Hauling in Underground Mines

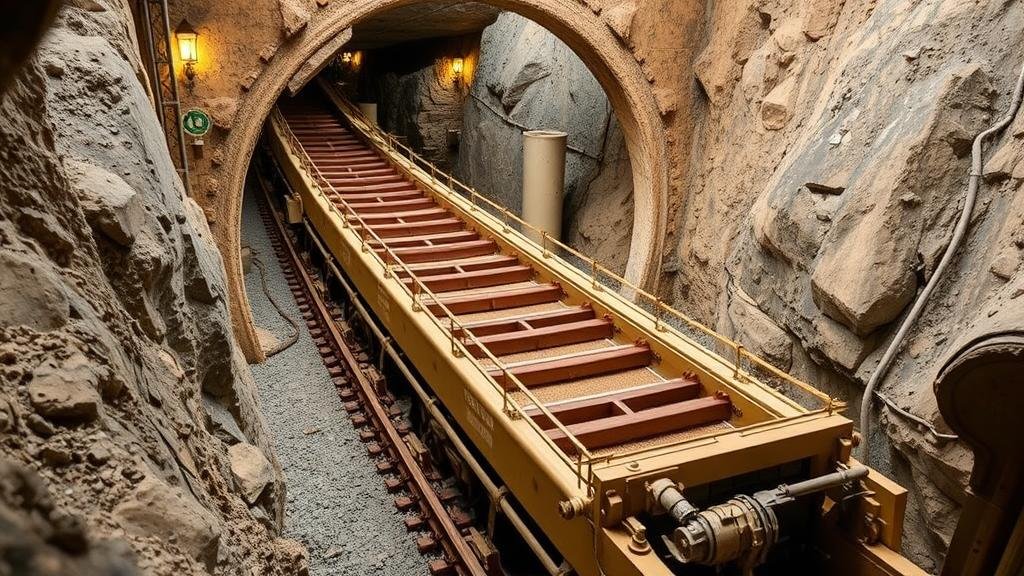

In the mining industry, the efficient movement of ore from underground mines to the surface is paramount for operational success and profitability. One innovative solution that has emerged is the construction of inclined planes, or ramps, which facilitate the transportation of ore with reduced energy expenditure and enhanced safety. This article explores the principles, advantages, and applications of inclined planes in ore hauling, while providing relevant case studies and actionable insights.

The Principles of Inclined Plane Design

Inclined planes are surfaces that deviate from the horizontal at an angle, allowing for the movement of materials under the influence of gravity. This design utilizes gravitational potential energy to assist in transporting ore, which can lead to significant reductions in hauling costs. The angle of inclination is crucial; while steeper angles can expedite transport, they may also increase the risk of slippage and require more robust support structures.

- The angle of inclination typically ranges between 15 and 30 degrees, balancing speed and safety.

- Proper surface materials, such as steel plates or rubberized coverings, can enhance traction and reduce wear on equipment.

Advantages of Inclined Planes in Ore Hauling

Inclined planes offer several advantages over traditional horizontal transport systems, such as shafts or conveyors. These advantages include:

- Cost Efficiency: By harnessing gravity, inclined planes can reduce the energy required for hauling ore, leading to lower operational costs.

- Reduced Equipment Wear: The gradual incline can minimize the wear and tear on hauling equipment, extending longevity and reducing maintenance costs.

- Streamlined Operations: Inclined planes can facilitate more straightforward logistics, as they allow continuous flow without the need for extensive shuttling.

- Safety Improvements: With proper engineering, inclined planes can reduce the risk of accidents associated with steep drop-offs in traditional mining operations.

Case Studies: Successful Useation of Inclined Planes

Several mining operations have successfully integrated inclined planes into their ore hauling processes. Notable examples include:

- Palabora Mining Company, South Africa: By implementing a system of inclined planes in their copper mine, they realized a 20% reduction in hauling costs. The design utilized a dual-lane ramp that enhanced traffic flow and improved safety protocols.

- Kansanshi Mine, Zambia: The application of inclined planes for transporting copper ore allowed for a 15% increase in haulage efficiency. The mines strategic positioning and the nature of its ore bodies made inclined transport an ideal solution.

Real-World Applications: The Operational Impact

The integration of inclined planes into mining operations can yield significant long-term benefits. For example, they provide a method to adapt to varying ore grade depths, allowing for sustained operations even as conditions change. These gradients can also be augmented with automated systems to optimize ore transport further.

Plus, a study by the International Council on Mining and Metals (ICMM) highlights that employing inclined planes can result in lower emissions from diesel-powered trucks, aligning mining operations with sustainability goals.

Addressing Potential Concerns

While inclined planes present many advantages, there are potential concerns that stakeholders should address:

- Structural Integrity: Ensuring robust construction materials and engineering support is critical to prevent collapses and ensure worker safety.

- Operational Fatigue: Continuous operation on an inclined plane may lead to fatigue in hauling equipment; thus, regular assessments and maintenance are necessary.

Actionable Takeaways

For mining operations considering the adoption of inclined planes for ore hauling, the following strategies are recommended:

- Conduct a comprehensive feasibility study to determine the optimal angle and design of the inclined plane.

- Invest in high-quality materials and engineering support to ensure the ramp’s structural integrity and safety.

- Use regular maintenance schedules to monitor wear and proactively address any safety issues.

- Train personnel on the unique operational demands of inclined planes to enhance safety awareness and efficiency.

To wrap up, the construction of inclined planes represents an innovative approach to improving ore hauling efficiency in underground mines. By carefully considering design parameters and implementing best practices, mining operations can significantly enhance their productivity, safety, and cost-effectiveness.