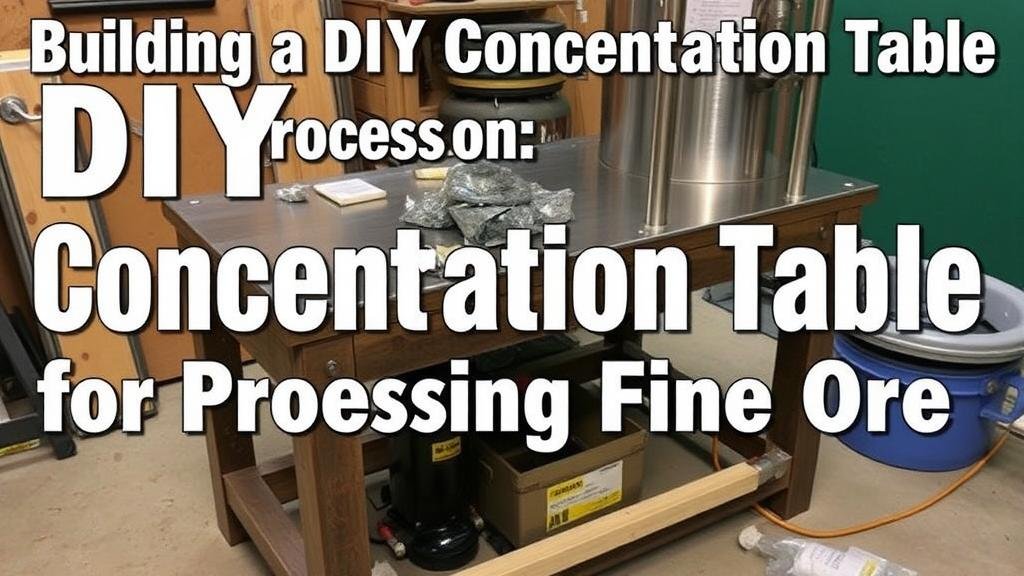

Building a DIY Concentration Table for Processing Fine Ore

Introduction

Building a DIY concentration table for processing fine ore can be an invaluable tool for hobbyists and small-scale miners alike. This guide will provide detailed instructions, highlight essential materials, and share best practices to construct a table that efficiently separates mineral particles based on their specific gravity.

Understanding Concentration Tables

A concentration table is a flat, inclined surface that uses gravity and motion to separate fine ore into valuable minerals and waste. These tables exploit the principle of density differences, where heavier particles settle faster than lighter ones. This process is akin to how a sieve separates larger stones from finer sand.

The Science of Gravity Separation

Gravity separation exploits the differences in specific gravity (SG) between materials. For example, gold has an SG of about 19.3, while quartz has an SG of approximately 2.7. This significant difference allows for effective separation using a concentration table.

Historical Context

Concentration tables have been used historically in various mining operations. Shaking Table, developed in the 19th century, has undergone refinements but remains a cornerstone of mineral processing. Its efficiency in recovering precious metals significantly contributed to the gold rushes in the United States and Australia.

Materials Needed for Construction

Before embarking on building your concentration table, it’s crucial to gather the right materials. Below are the necessary components:

- Sheet of plywood (3/4 inch thick)

- Two long strips of 1×4 lumber

- Vibrating motor or an old electric motor

- Rubber mats or non-slip material

- Fine mesh screen or perforated plate

- Leveling feet or adjustable legs

- Water supply and recirculation system (e.g., a pump)

- Connectors, screws, and adhesive

Building the DIY Concentration Table

Step 1: Design and Framework

Begin by constructing the rectangular frame of the table using the plywood and 1×4 lumber. table should have an incline of 5-15 degrees to enhance the separation process. Properly securing the structure is essential, so ensure each connection is robust and stable.

Step 2: Installing the Vibrating Mechanism

Attach the vibrating motor securely to one end of the table. If using an old electric motor, ensure it is well-balanced to avoid excessive shaking or damage. vibration helps to move the materials across the table, facilitating separation.

Step 3: Surface Preparation

Cover the table surface with rubber mats or non-slip material to provide friction, allowing the particles to settle appropriately. The mat should be durable enough to withstand regular use during ore processing.

Step 4: Adding Water System

Install a water supply that evenly distributes water across the table. Water plays a crucial role in the separation process, helping to wash away lighter materials while allowing heavier particles to sink.

Step 5: Testing and Calibration

Once assembled, test the concentration table with a small sample of ore. Adjust the water flow and the angle of the table to optimize the separation efficiency. Conduct several trials to fine-tune the setup, aiming for maximum recovery of desired minerals.

Real-World Applications and Case Studies

DIY concentration tables have been successfully utilized in various commercial and recreational ventures. For example, many small-scale miners in regions like Alaska and Canada use homemade tables to efficiently recover gold from tailings. In a case study conducted by the Mineral Processing Journal, a small mine was able to increase gold recovery rates by nearly 30% by implementing a custom-built concentration table alongside their existing processing methods.

Conclusion

Constructing a DIY concentration table is a rewarding project that enables effective processing of fine ore. By understanding the principles of gravity separation and utilizing the right materials and techniques, individuals can create a functional tool that enhances mineral recovery. Whether for hobby or enterprise, this knowledge can lead to significant advancements in one’s ore processing capabilities.

Actionable Takeaways

- Thoroughly research materials and designs before beginning construction.

- Prioritize safety when working with tools and machinery.

- Experiment with various settings during testing to maximize efficiency.