The Role of Scaling Bars in Clearing Loose Rock Safely

The Role of Scaling Bars in Clearing Loose Rock Safely

In geological and mining operations, the presence of loose rock poses significant risks to workers safety and can impede progress. Scaling bars are critical tools used to manage and mitigate these hazards. This article explores the function, application, and importance of scaling bars in ensuring a safer working environment in rock-related tasks.

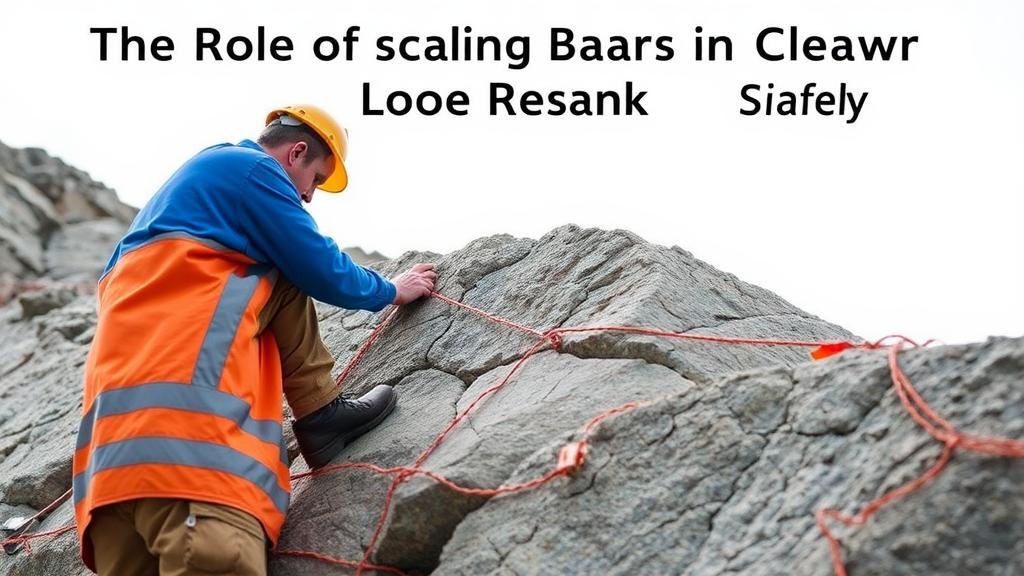

Understanding Scaling Bars

Scaling bars, also referred to as scaling tools or demolition bars, are long, typically steel bars equipped with features designed to dislodge and remove unstable rock or debris from surfaces. e tools can vary in design, but they are usually around 5 to 12 feet long and may have hooks, chisel tips, or other features aimed at enhancing safety and effectiveness.

The Function of Scaling Bars

The primary function of scaling bars is to allow workers to safely remove loose rock, commonly known as scaling. Scaling involves clearing away unstable material to prevent it from falling and causing injuries or accidents. Scaling bars enable workers to reach elevated or hard-to-access areas while maintaining a safe distance from potential falling debris.

- Prevention of accidents: Scaling bars help control rock fall risks, drastically reducing accident rates in mining and construction sites.

- Efficient debris removal: These tools facilitate quick dislodging of loose materials, which improves workflow and productivity.

- Enhanced worker safety: By allowing workers to maintain distance from hazardous areas, scaling bars contribute to a safer working environment.

Application in Mining and Construction

Scaling bars are widely used in both mining operations and construction sites. In underground mining, workers often encounter rock formations with loose material threats. Scaling bars are used during the scaling process to stabilize walls and ceilings, which is crucial for preventing rock falls that can be fatal.

In construction, scaling bars serve a similar purpose when preparing sites for excavation. For example, during tunnel construction, large amounts of loose rock can become dislodged and fall if not managed. Workers use scaling bars to remove these hazards systematically, ensuring safety for personnel and equipment alike.

Real-world applications demonstrate the effectiveness of scaling bars. For example, a mining operation in a region known for unstable rock formations reported a 30% decrease in rock fall incidents after integrating scaling bars into their safety protocols. This improvement not only increased worker safety but also resulted in fewer project delays and reduced costs related to accidents.

Best Practices for Using Scaling Bars

To maximize the effectiveness of scaling bars and enhance safety, workers should adhere to several best practices:

- Conduct training: Workers should receive training on the proper use of scaling bars to understand their design and functionalities fully.

- Inspect tools regularly: Regular inspections can prevent tool failures that could lead to accidents.

- Work in teams: Utilizing the buddy system ensures that multiple people are present during high-risk scaling operations, promoting safety and assistance when needed.

Addressing Concerns

While scaling bars are effective, some concerns regarding their usage exist. Key among these is the potential for worker fatigue due to the physical exertion required to use these tools vigorously, particularly in challenging conditions. Strategies to mitigate this include regular breaks and alternating tasks to reduce fatigue.

Also, the risk of improper use can lead to accidents. But, comprehensive training programs can address this issue, ensuring workers are aware of safe practices and potential hazards.

Conclusion

Scaling bars play a crucial role in the safe management of loose rock in mining and construction industries. Their primary functions of preventing accidents and facilitating efficient debris removal make them indispensable tools. By adhering to best practices and understanding the importance of scaling bars, organizations can enhance worker safety and operational efficiency.

In consideration of the information presented, stakeholders in relevant industries should prioritize the integration of scaling bars and their proper use, ensuring a safer working environment and fostering a culture of safety that mitigates risks associated with loose rock.