Understanding Ore Blending for Improved Recovery in Small Mining

Understanding Ore Blending for Improved Recovery in Small Mining

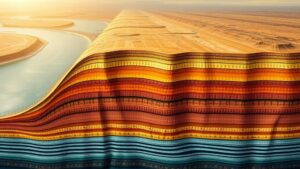

Ore blending is a critical process in the mining industry, particularly for small-scale operations that may not have the resources to invest heavily in advanced technology. This article explores the significance of ore blending, its processes, and how it can enhance recovery rates in small mining operations.

The Importance of Ore Blending

Ore blending involves mixing different types of ore to optimize the quality and quantity of minerals extracted during processing. This practice is essential for improving metal recovery, which can directly impact the economic viability of a mining project. According to a study by the Mining Industry Coordinating Council, effective blending can increase recovery rates by 10-20%.

Types of Ore and Their Characteristics

Different types of ore possess various qualities that can affect their recoverability. Understanding these characteristics is crucial for effective blending.

- Sulphide Ores: These typically require flotation for recovery and can present challenges due to varying mineral compositions.

- Oxide Ores: Often processed using heap leaching, oxide ores can vary in their chemical properties, affecting acid consumption rates.

- Mixed Ores: Containing both sulphide and oxide materials, mixed ores require careful handling to optimize recovery methods.

Processes and Techniques for Ore Blending

The methodology for ore blending can be broken down into several stages, each with a focus on optimizing recovery.

- Characterization: Assessing the quality and properties of available ore types using techniques such as chemical assays and mineralogical studies.

- Batch Blending: Mixing predetermined percentages of different ores prior to processing to achieve a desired grade.

- Dynamic Blending: Adjusting the blend in real-time during processing based on ongoing assays and recovery metrics.

Case Studies: Successful Ore Blending

Several small mining operations have employed ore blending strategies effectively. For example, the Kumtor Gold Company in Kyrgyzstan utilizes a sophisticated blend of oxide and sulphide ores that has resulted in enhanced recovery rates and a 15% reduction in processing costs. r approach to dynamic blending allows them to respond to fluctuations in ore quality rapidly.

Challenges of Ore Blending in Small Mining

While ore blending offers numerous benefits, small-scale miners face certain challenges:

- Limited Resources: Small mining operations may lack the technology and expertise needed for effective blending.

- Inconsistent Ore Quality: Variability in ore quality can complicate blending processes and outcomes.

- Economic Constraints: Initial investment in blending technology may be prohibitive for small-scale miners.

Real-World Applications: Optimizing Recovery Through Blending

To maximize recovery through ore blending, miners can apply specific strategies:

- Regular Monitoring: Use regular sampling and analysis to inform blending decisions.

- Training and Capacity Building: Invest in staff training to enhance understanding of ore characteristics and blending processes.

- Collaboration: Small miners can form cooperatives to share resources and expertise in blending practices.

Conclusion

To wrap up, ore blending is a fundamental technique that can significantly improve recovery rates in small mining operations. By understanding the types of ore, employing effective blending processes, and addressing associated challenges, small-scale miners can enhance their operational efficiency and financial viability. Incorporating these strategies not only fosters sustainability in their processes but also contributes to the overall growth of the mining industry.