How to Use Portable XRF Devices to Analyze Rock for Precious Metals

How to Use Portable XRF Devices to Analyze Rock for Precious Metals

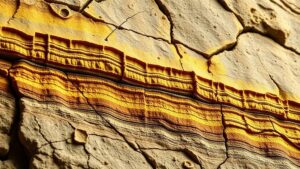

Portable X-ray fluorescence (XRF) technology has revolutionized the field of mineral exploration and analysis, particularly in the assessment of rocks for precious metals. This portable, non-destructive technique allows geologists and mining professionals to quickly and accurately quantify the elemental composition of geological samples in the field, facilitating informed decision-making and enhancing exploration efficiency.

Understanding Portable XRF Technology

Portable XRF devices operate by emitting X-rays that interact with the atoms in a sample. When the X-rays hit the sample, they excite the atoms, causing them to emit secondary X-rays. device detects these secondary rays and processes the data to provide a detailed elemental analysis. This technology is capable of detecting light elements such as magnesium and aluminum as well as heavy metals like gold, silver, and lead, making it particularly useful in precious metal exploration.

Benefits of Using Portable XRF Devices

The adoption of portable XRF technology offers several significant advantages:

- Rapid Results: Data can be obtained within minutes, allowing for real-time decision-making.

- Field Deployability: The devices are compact and lightweight, making them easy to transport to remote locations.

- Non-Destructive Testing: Unlike traditional laboratory methods, portable XRF analysis does not alter the sample.

- Cost-Effectiveness: Reduces the need for extensive sample transport and laboratory analysis, saving both time and resources.

Preparing for Analysis

The preparation for using portable XRF devices involves several steps to ensure accurate results:

- Selecting Samples: Choose representative rock samples that are homogenous and free from contamination.

- Cleaning the Surface: Ensure the rock surface is clean from dirt, dust, and moisture to prevent interference during analysis.

- Calibrating the Device: Regular calibration with certified reference materials is necessary to maintain accuracy.

Conducting the Analysis

Once prepared, the analysis can begin. Here’s a step-by-step guide:

- Positioning the Device: Place the XRF analyzer in direct contact with the rock surface. Ensure that there is no gap between the device and the sample.

- Selecting the Mode: Choose the appropriate analysis mode on the device, typically either ‘soil’ or ‘rock’ mode. Fine-tuning may be necessary based on the expected elemental makeup.

- Initiating Analysis: Activate the analyzer and let it run the analysis for the recommended duration, usually between 30 seconds to 2 minutes for optimum results.

- Interpreting the Data: After analysis, review the data on the device’s screen, which often includes concentrations of elements and a qualitative summary.

Interpreting Results

The results obtained from portable XRF analysis provide valuable insights. High concentration levels of elements such as gold (Au) and silver (Ag) can indicate potential ore deposits. A common evaluation metric is the cut-off grade, which refers to the minimum concentration of a mineral that can be economically extracted. For example, a threshold of 3 grams per tonne (g/t) of gold may signify a viable deposit. Professionals often compare XRF results against established geological data to validate findings.

Case Study: Successful Application in the Field

A prominent example of portable XRF use is seen in the exploration efforts of a mining company in Nevada, known for its rich gold deposits. By employing portable XRF devices, geologists were able to quickly analyze multiple samples from various drill sites. The rapid data acquisition revealed a previously unnoticed vein of gold-rich ore, which led to a re-evaluation of the site’s mining potential. This case emphasizes how portable XRF can lead to significant economic benefits in mineral exploration.

Limitations and Considerations

While portable XRF offers numerous benefits, it also has limitations:

- Elemental Detection Limits: Portable XRF may not detect all elements with the same sensitivity, particularly light elements like lithium.

- Matrix Effects: The composition of the sample can interfere with the readings, necessitating careful sample selection.

- Regulatory Compliance: Depending on jurisdiction, specific guidelines may govern the use of XRF technology, requiring proper training and certification for operators.

Conclusion and Actionable Takeaways

To wrap up, portable XRF devices stand out as powerful tools for analyzing rock for precious metals. r rapid, non-destructive methodology offers significant advantages in mineral exploration, leading to informed decisions and increased operational efficiency. To effectively utilize this technology:

- Invest in proper training for users to understand device operation and data interpretation.

- Incorporate portable XRF analysis into routine geological surveys to enhance exploration strategies.

- Use the data in conjunction with traditional geological analysis for a comprehensive understanding of potential mineral deposits.

By embracing portable XRF technology, mining professionals and geologists can conduct more effective field analyses, leading to cost-effective exploration and enhanced resource discovery.