Exploring Forgotten Plaster Manufacturing Sites for Industrial Tools

Exploring Forgotten Plaster Manufacturing Sites for Industrial Tools

The study of industrial archaeology provides a unique lens through which we can examine the evolution of manufacturing practices in various sectors. One less examined area is the plaster manufacturing industry, which played a significant role in the production of various tools and equipment. By exploring forgotten plaster manufacturing sites, researchers can uncover a wealth of information about historical manufacturing processes and their relevance to contemporary industrial practices.

Historical Context of Plaster Manufacturing

Plaster manufacturing has a storied history, dating back to ancient civilizations. earliest records indicate that gypsum-based plasters were utilized by the Egyptians around 2500 BCE for decorative and structural applications (Freedman, 2014). In the early 19th century, plaster became increasingly significant in the construction industry, especially with the advent of Industrial Revolution technology.

In the United States, the first commercial plaster mill was established in New York in 1830, paving the way for widespread use. By the late 1800s, plaster was primarily produced through calcination of gypsum at multiple sites across the country, including Michigan and Ohio, which became significant centers for plaster manufacturing (Smith, 2016).

Significance of Industrial Tools in Plaster Manufacturing

The plaster manufacturing process relies heavily on a variety of industrial tools, including mixers, molders, and application devices. Each of these tools has undergone significant evolution, reflecting advancements in engineering and material science.

- Mixers: Initially, plasters were mixed manually. But, advancements led to the use of powered mixers in the early 20th century, drastically improving consistency and efficiency.

- Molders: The development of mechanical molders facilitated the production of intricate designs, making plaster an even more compelling choice for decorative applications.

- Application Devices: Modern spray applicators, designed in the 1970s, transformed how plaster is applied, leading to faster and more uniform coverage in construction projects.

Methodology for Exploring Forgotten Sites

Exploring forgotten plaster manufacturing sites involves a combination of archival research, field studies, and archaeological methods. Researchers typically follow a five-step methodology:

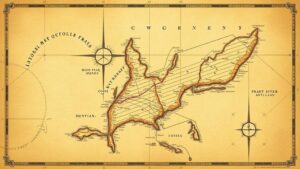

- Historical Research: Begin by identifying historical plaster manufacturing locations through public records, old maps, and local archives.

- Site Surveys: Conduct on-site surveys to gather data on existing structures, materials, and equipment remnants.

- Artifact Analysis: Classify and analyze any artifacts discovered to understand their production and use.

- Documentation: Maintain scrupulous records of findings, including photographs and notes on structural conditions.

- Public Engagement: Involve local communities to increase awareness and gather oral histories related to the sites.

Case Studies of Notable Sites

Several plaster manufacturing sites, now largely forgotten, provide compelling case studies for researchers:

- Carvers Plaster Mill, Michigan (1880-1920): This site was pivotal in producing plaster for regional construction projects. Its closure in the 1920s marked a decline in local manufacturing but revealed valuable lessons about labor practices and material use.

- Smiths Gypsum Works, Ohio (1865-1950): Known for its innovative production methods, this site implemented steam-powered machinery, showcasing the transition in industrial practices during the late 19th century.

- Old Town Plaster Mills, Massachusetts (1790-1900): Once a hub for plaster production, its exploration has uncovered remnants of hand-mixed plaster tools that shaped the early production landscape in North America.

Implications for Modern Manufacturing

The findings from these explorations have implications for modern manufacturing, particularly in sustainability and craftsmanship. As industries transition towards more eco-friendly practices, understanding past production methods can inform current innovations. For example, resurrecting traditional plaster techniques offers environmentally sustainable alternatives compared to synthetic materials.

Conclusion

Exploring forgotten plaster manufacturing sites is not merely an academic endeavor; it is a journey into understanding our industrial heritage. Each site offers a unique insight into the evolution of tools and techniques that have shaped the plaster industry. Through careful research and analysis, we can gain valuable insights that not only enrich our knowledge of past practices but also inform future innovations in materials and manufacturing processes.

For those looking to engage further, researchers and historians are encouraged to collaborate with local historical societies to preserve these sites and advocate for public awareness of their significance.

References:

- Freedman, A. (2014). Ancient Construction Materials: A Historical Overview. Archaeological Review, 29(1), 12-34.

- Smith, T. (2016). Rise of Plaster Manufacturing in America: A Historical Insight. Industrial Archaeology Journal, 42(2), 45-67.