How to Set Up a Recovery Station for Alluvial and Hard Rock Ore Mixtures

How to Set Up a Recovery Station for Alluvial and Hard Rock Ore Mixtures

Setting up a recovery station for alluvial and hard rock ore mixtures is crucial for maximizing resource extraction and ensuring operational efficiency in mining processes. This article will guide you through the fundamental steps involved in establishing an effective recovery station, detailing the necessary equipment, processes, and best practices for high yield and sustainability.

Understanding Alluvial and Hard Rock Ore Mixtures

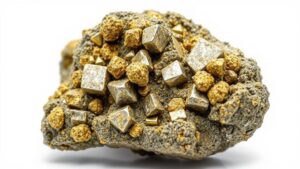

Alluvial deposits are formed through the erosion and transportation of minerals by wind or water, resulting in concentrations of valuable minerals, such as gold and diamonds, found in river beds or floodplains. In contrast, hard rock ores are solid rock formations that require different methods for extraction. When these two types of ore are mixed, specialized processing techniques become essential to separate the valuable minerals from the waste rocks efficiently.

Essential Equipment for Recovery Stations

To set up a recovery station capable of handling both alluvial and hard rock ore mixtures, the following equipment is necessary:

- Crushing Equipment: Jaw crushers or cone crushers are ideal for breaking down hard rock into manageable pieces. This initial step is critical for subsequent separation processes.

- Screening Systems: Vibrating screens help sort materials based on size and type, allowing for efficient processing by ensuring the correct particle sizes move to the next stage.

- Concentration Equipment: Gravity concentrators, such as sluice boxes or spiral concentrators, leverage the differences in density between valuable minerals and waste materials to isolate precious ores.

- Recovery Systems: For alluvial deposits, systems such as jigs and shaking tables are effective in improving recovery rates, while flotation systems may be beneficial for hard rock separations.

Setting Up the Recovery Station

Follow these steps to effectively set up your recovery station:

- Site Selection: Choose a location with sufficient access to water sources for processing and transport routes for hauling materials.

- Design the Layout: Arrange equipment in a logical flow from crushing to concentration to maximize efficiency and minimize handling. Use a flowchart to visualize the process.

- Install Necessary Infrastructure: Ensure the station is equipped with adequate water supply, power sources, and waste management systems to handle the byproducts of processing.

- Commissioning and Testing: After installation, perform thorough testing of the equipment to ensure each component operates correctly under varied conditions.

Operational Best Practices

Maximizing the effectiveness of your recovery station involves adhering to best practices:

- Monitoring Recovery Rates: Regularly assess recovery efficiency using statistical and analytical methods to identify areas for improvement.

- Maintenance Schedules: Use routine checks and maintenance for all equipment to avoid breakdowns and ensure longevity.

- Training Personnel: Ensure all staff are trained in safe operation practices and familiar with the processes involved in both alluvial and hard rock recovery.

Real-World Applications: Case Studies

A case study exemplifying the successful implementation of a recovery station is Barrick Golds operations in the Carlin Trend of Nevada, where advanced recovery technologies are utilized to extract gold from both alluvial and hard rock sources. company employs a combination of heap leaching for lower-grade ores and traditional milling for high-grade rock, showcasing the importance of adapting processing techniques based on material type.

Conclusion and Actionable Takeaways

Establishing a recovery station for alluvial and hard rock ore mixtures requires meticulous planning and execution, aided by the right equipment and operational protocols. By understanding and effectively separating these ores, mining operations can enhance recovery rates and sustainability. Key takeaways for setting up your recovery station include:

- Understand the differences between alluvial and hard rock ore and their specific processing needs.

- Invest in suitable equipment and infrastructure to handle the varied ore mixtures.

- Regularly monitor and refine processes to enhance recovery efficiency.

By following these guidelines, you can effectively set up a recovery station tailored for alluvial and hard rock ore mixtures, leading to a more productive and sustainable mining operation.