Recovering Silver From Narrow Ore Veins Exposed in Rock Outcrops

Recovering Silver From Narrow Ore Veins Exposed in Rock Outcrops

Silver recovery from narrow ore veins is a critical aspect of the mining industry, especially in areas where high-grade silver occurs within distinct geological formations. This article explores the methods and techniques used to extract silver efficiently from these exposed veins, the challenges faced, and the overall significance of this process in both economic and environmental contexts.

Understanding Ore Veins

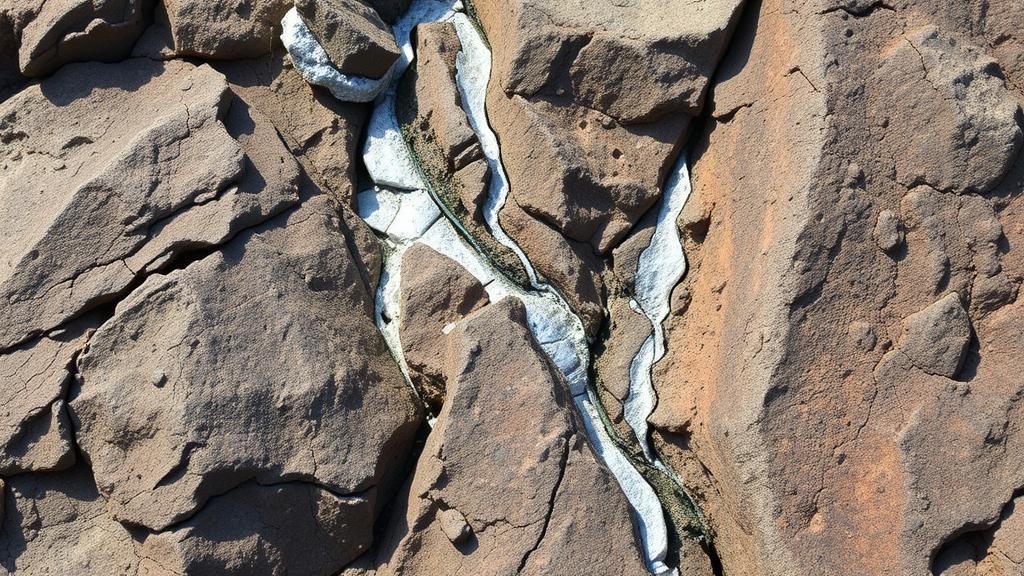

Ore veins are geological formations where minerals are deposited in distinct, often narrow bands. Silver is frequently found alongside other base and precious metals, such as lead and gold, within these veins. unique geological processes that lead to the formation of silver-rich veins are important to understand for effective extraction.

Typically, silver veins are formed through hydrothermal processes, where hot, mineral-rich water moves through rock fractures, depositing minerals as it cools and loses pressure. These veins can range in thickness from a few centimeters to several meters, making retrieval methods crucial for maximizing yield.

Techniques for Silver Recovery

Several methods can be employed to extract silver from narrow ore veins, depending on factors such as vein width, ore grade, and the surrounding geological environment. The following are some of the most notable techniques:

- Cut and Fill Mining: This method involves excavating ore in horizontal sections and then filling the mined area with waste materials. This technique is especially effective for steeply dipping veins.

- Room and Pillar Mining: In this method, miners carve out rooms in the ore body while leaving pillars of ore to support the ceiling. This technique is often used in wider veins.

- Long Hole Stoping: This involves creating large vertical holes in the ore body and blasting it. The fragmented ore is then removed for processing.

Processing the Ore

Once the ore has been extracted, it must be processed to separate the silver from other metals and minerals. Common processing methods include:

- Flotation: This process uses chemicals to induce bubbles that allow silver-containing particles to rise to the surface for removal. It is highly effective for low-grade ore.

- Cyanidation: In this method, cyanide is leached through crushed ore, allowing silver to dissolve and be later recovered from the solution.

- Electrowinning: This is a direct electrochemical process where silver is plated out of solution, resulting in high-purity silver crystals.

Challenges in Silver Recovery

Recovering silver from narrow ore veins is not without challenges. Some of the primary issues include:

- Environmental Concerns: Mining operations can have detrimental impacts on local ecosystems, necessitating rigorous management and recovery practices.

- Financial Viability: The thin nature of these veins may lead to increased operational costs, making it essential to conduct a thorough cost-benefit analysis before mining.

- High Competition: The silver market is competitive, affecting pricing and investment opportunities.

Case Studies and Real-World Applications

Case studies in regions such as Nevada and Mexico demonstrate the complexity of silver recovery from narrow veins. Comstock Lode in Nevada, for example, showcases significant historical silver mining success, employing various techniques that have evolved over time.

In Mexico, the Fresnillo District has become one of the worlds leading silver-producing regions, utilizing advanced technologies to enhance recovery rates while adhering to sustainable practices. These real-world applications highlight not only the technical aspects of silver recovery but also the socio-economic impacts of successful mining operations.

Conclusion

Recovering silver from narrow ore veins exposed in rock outcrops involves a combination of geological understanding, technical proficiency, and environmental stewardship. As technologies advance and the demand for silver continues, mining operations must balance profitability with sustainable practices.

In summary, mining professionals should consider:

- Utilizing modern mining techniques tailored to specific geological constraints.

- Useing effective ore processing methods to maximize silver recovery rates.

- Engaging in community and environmental planning to mitigate the negative impacts of mining operations.

By addressing these factors, the silver mining industry can thrive while meeting global demands and contributing to local economies.