Maximizing Recovery with Multi-Stage Sluicing Systems

Maximizing Recovery with Multi-Stage Sluicing Systems

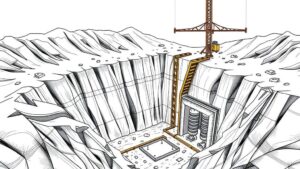

Multi-stage sluicing systems are an advanced method employed to enhance the recovery rates in mineral processing, particularly in gold and other heavy mineral extraction. These systems utilize a series of sluice boxes or channels designed to optimize the separation of valuable minerals from waste material. This article explores the principles, stages, benefits, and applications of multi-stage sluicing systems, aiming to provide a comprehensive understanding of their role in recovery maximization.

Understanding Multi-Stage Sluicing Systems

A multi-stage sluicing system operates by breaking down the mining and separation process into several distinct phases. Each stage is engineered to capture different particle sizes and densities, thereby increasing the overall effectiveness of the recovery process. The fundamental principle revolves around water flow and the gravitational settling of materials.

Stages of Multi-Stage Sluicing Systems

Multi-stage sluicing systems typically comprise three or more complementary stages, each serving a specific purpose:

- Primary Sluicing: The first stage where larger particles are separated from finer materials. In this stage, a high flow rate helps mobilize materials, allowing heavier particles to settle quickly.

- Secondary Sluicing: This stage focuses on the recovery of medium density particles. flow rate is adjusted to optimize the separation of valuable minerals from sands and lighter debris.

- Tertiary Sluicing: The final stage aims to capture fine particles that may have bypassed earlier stages. This often involves a combination of controlled water flow and specialized sluice designs to maximize mineral retention.

Benefits of Multi-Stage Sluicing Systems

The implementation of multi-stage sluicing systems offers several significant advantages:

- Increased Recovery Rates: By capturing particles across a broader spectrum of sizes and densities, multi-stage systems often achieve recovery rates exceeding 90%, compared to traditional systems which might only recover 70-80%.

- Cost Efficiency: Improved recovery reduces waste materials, thereby lowering processing costs associated with waste management.

- Environmental Impact: By maximizing the recovery of valuable minerals, these systems contribute to reduced environmental disruption associated with mining operations.

Case Study: Application in Gold Mining

Consider the application of multi-stage sluicing systems in an established gold mining operation in Western Australia. Traditionally, the mine employed single sluice systems that resulted in considerable gold losses during the processing of ore. After transitioning to a multi-stage approach, with careful adjustments to water flow and sluice configurations, the operation saw a recovery rate improvement from 75% to 92%.

This case highlights the critical role multi-stage systems played not only in recovering additional gold but also in optimizing the operational workflow, thereby enhancing overall productivity.

Addressing Common Concerns

While multi-stage sluicing systems present numerous advantages, potential users may have concerns regarding the initial investment and complexity of implementation. It is essential to weigh these considerations effectively:

- Initial Investment: The upfront cost may be higher due to the need for specialized equipment. But, the long-term gains from increased recovery and reduced operational costs often justify the expense.

- Operational Complexity: Multi-stage systems require more intricate operational management. Providing adequate training and resources can mitigate this concern and ensure smooth operations.

Conclusion and Actionable Takeaways

To wrap up, multi-stage sluicing systems offer an exceptional method for maximizing recovery rates in mineral processing. The stages–primary, secondary, and tertiary–work synergistically to optimize the extraction of valuable resources while minimizing waste. Given the substantial benefits, including increased recovery rates, cost efficiency, and reduced environmental impact, mining operations should consider investing in such systems to enhance their processing capabilities.

Key takeaways include:

- Evaluate the specific needs of your operation to determine the feasibility of a multi-stage sluicing system.

- Consider the potential for increased recovery rates and overall efficiency when investing in new equipment.

- Ensure proper training and operational protocols are in place for effective management of multi-stage systems.

By adopting a multi-stage sluicing approach, mining operations can significantly improve their mineral recovery efforts, ensuring economic viability in an increasingly competitive industry.